Process and finish

Rotomoulding is a plastic processing technique. The technique is based on the rotation and heating of a mould. These two elements together marry the plastics gradually to the shape of the mould. Thus was born the word rotomoulding - moulding by rotation. In practice, there are five steps in processing the plastic:

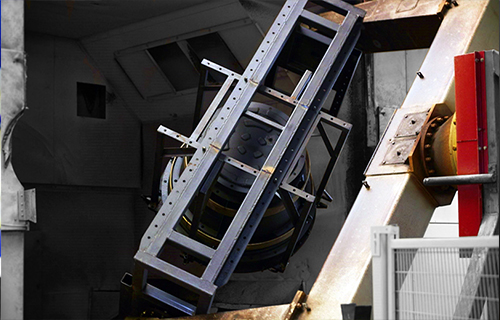

Step 1: Loading and closing the mould

A mould is normally formed of two half-shells, one fixed and the other mobile. The fixed part is loaded with plastic powder or liquid plastisol weighing the same as the part being produced. The mould is then closed. The fixed mould part has been fitted in advance on a mechanical system which allows it turn around two perpendicular axes

Step 2: Rotating in two perpendicular axes

The material mould assembly starts to move and the mould then turns in all directions. The plastic powder drips by gravity onto the walls. There is negligible centrifugal force as rotating speeds are slow.

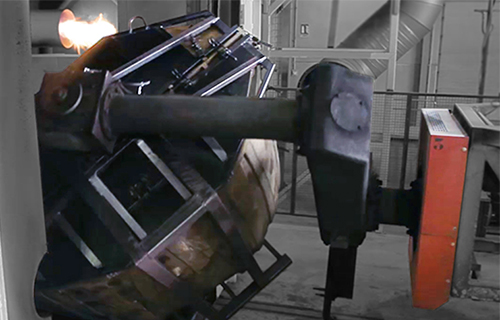

Step 3: Heating the mould to the correct melting temperature

The plastic mould assembly is then heated by heat from an oven, a gas manifold or infrared panels. The metal mould then heats up and transmits its heat to the powder. The powder grains start to melt and then adhere to the mould walls. Melting continues until one by one all the grains are melted. This means that the temperature for correct melting of the material has been reached on the last coat, which is the internal face of the moulded part.

Step 4: Solidifying the materials

At the end of the heating period, the thermoplastic material is at a higher temperature than its melting point and its consistency is still viscous. It must therefore be cooled. This is achieved by projecting cool air and/or a water mist onto the mould. When the material has dropped below its crystallisation or solidification temperature, cooling continues until it can be handled.

Step 5: Demoulding

The part obtained is sufficiently rigid and cold. The mould is opened, the mobile part of the mould is raised and the part is extracted. This has taken on exactly the internal architecture of the mould. The part is thus ready for finishing or assembly with other parts.